The 1FastGuard™ Touring Guard™ conformable push-on stone guards are Jaeger Brothers Automotive Accessories, latest creation.

Our slip-on/push-on splash/stone guards have been protecting classic and late model Mustangs from stone chips and paint damage since 2005, and over the years we have seen hundreds of additional applications for our slip-on splash guards, but it is not always possible to custom design a product for every variation and sub-model of car or truck available.

We created the Touring Guard to fit all of those applications and more, it is perhaps the most innovative, functional and discreet stone guard ever created.

Originally designed for concours and show cars. Fits 100's of classic and late model applications.

Push-on installation, conforms to fit, installs in seconds. Made in the USA

Grabs the fender flange safely and securely.

No drilling, No screws, No tape. Can be easily installed by almost anyone, with no tools.

Designed for every day, all-season use, or just when you are touring.

Made with soft materials that will not damage your paint.

Designed for people who care about protecting and preserving their vehicles.

Sometimes called mud flaps, splash guards, mud guards, rock guards or a spray supression device. Which attach to the fender flange of the wheel well, wheel opening or wheel arch, of the fender, quarter panel or bumper.

________________________________________________________________

Why do you need stone guards?

As you drive down the road... Directly behind your spinning wheels is a spray of road debris, rocks, sand, etc. This wheel spray is thrown against the fender and side of the vehicle, and can quickly damage a vehicles paint.

Stone guards are known to help protect the vehicle from damage due to debris thrown from the wheels.

Once the damage has been done, it is not only unsightly, but expensive to repair.

If you want to maintain the value of your car and keep it looking better longer, you need a protective barrier.

As seen below.

________________________________________________________________

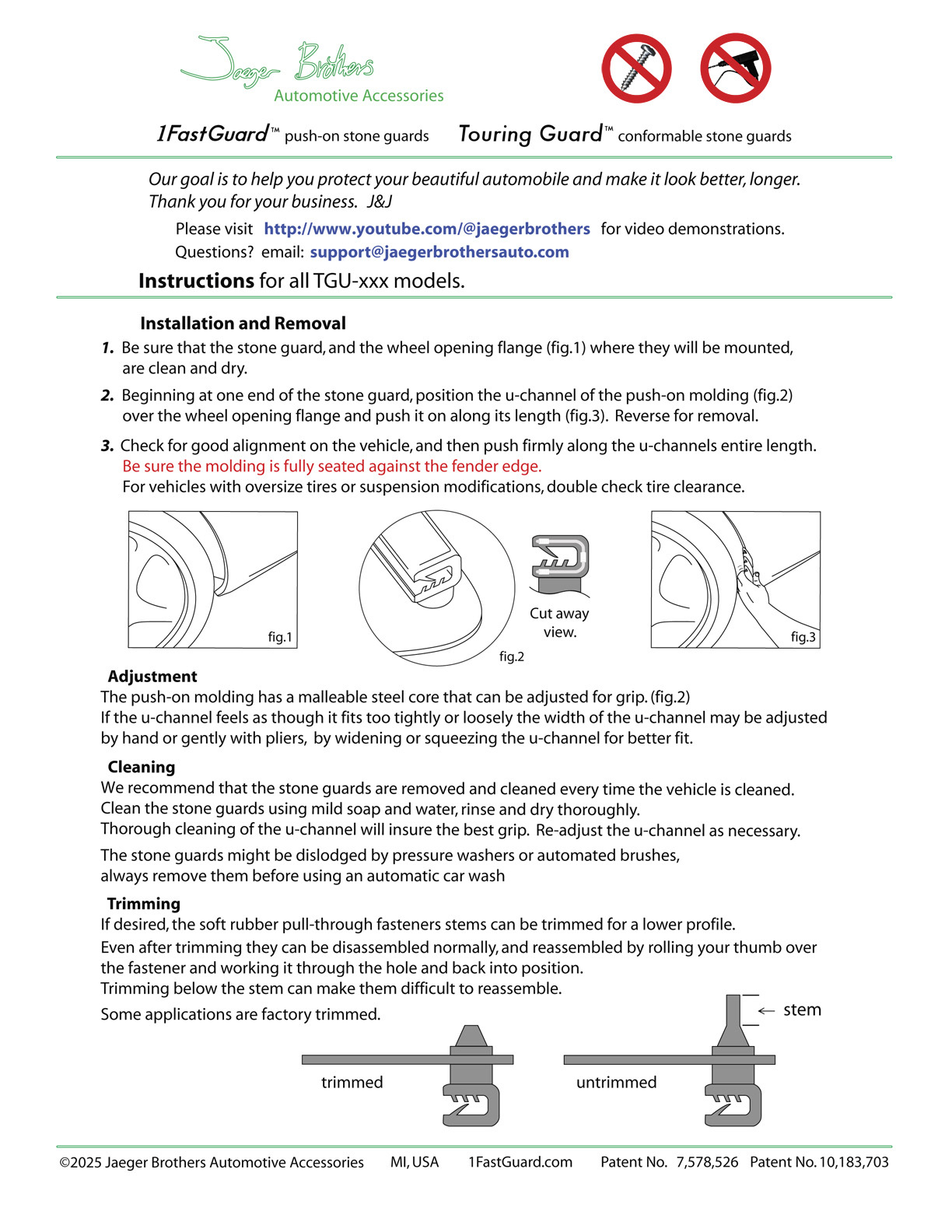

Fender Flanges

Jaeger Brothers Automotive Accessories have been making our patented slip-on splash guards since 2005, they install in seconds by gripping the edge of the wheel opening fender flange, and offer a fast and easy solution to help protect your vehicle from stone chips and splash.

Wheel opening flanges or wheel arch flanges, also known as a fender flange, are very common on old and new cars, it is the curved flange of the wheel opening parallel to the tire, and adds stiffness and visual appeal to the fender, quarter panel or bumper. Most often the shape of the fender flange is unique to each make and model.

Much of the time these fender flanges are open and readily accessible to mount our stone guards to, we refer to this as an open fender flange.

If your flange is obstructed by fasteners, a rigid inner fender liner, or a liner that hides the flange. These products may not work for you, but if you can fit a bit of your finger behind the flange these should work well.

Our products are designed to mount only to open fender flanges.

The fender flange and the side of your vehicle are repeatedly bombarded by stones thrown up by your tires, which can result in damage to these painted surfaces in a short amount of time.

Touring Guards bend in three dimensions to fit almost any fender flange shape, without buckling or stretching. Like scales or petals, they overlap and create a very effective barricade.

Painted sheet metal flanges usually range in width from .375" to over 1".

Plastic flanges, painted or textured, are found on many modern cars and trucks, and may range from .375" wide to several inches.

For wider flanges we offer different sizes/styles of scales for greater coverage and protection. Our push-on molding is designed to attach well to all flanges as small as .36" wide and may not fit flanges smaller than this firmly.

Flange thickness varies from vehicle to vehicle as well. The malleable metal core in our push-on molding allows it to be adjusted by hand or gently with pliers to adjust grip and fit various panel thicknesses securely. The Push-on molding fits flanges from .030" to .125" thick.

Vulnerable painted wide-open fender flanges are common on classic cars and trucks, high end imports, exotics and many others, protect them with a Touring Guard stone guard.

The 1FastGuard™ push-on stone guards grip the edge of the wheel opening flange, and provide instant protection.

The Touring Guard™ stone guards patented design allows it to bend in three dimensions to fit nearly any fender flange.

________________________________________________________________

Sizes

Touring Guard stone guards are available in various lengths to accommodate different coverage needs and applications.

Grab a flexible ruler and measure the length of your fender flange.

We designed the 8" length stone guard to be the standard size because it covers the most applications easily and provides almost 9" of barricade, but some vehicles may need shorter models, or will need to chain them together.

If you would like to provide coverage for a larger area, the parts are easily chained together to form one long stone guard of practically any length. Chaining two stone guards together results in a 1" gap between the two push-on molding parts for clearing obstacles if necessary.

Additional scales for chaining are included for free when you order two sets or more of any size.

Currently available in three scale sizes with MiniFlaps available in all sizes.

Style A "standard profile" is designed for vehicles with a wide .75" to 1.5" fender flange, and provide roughly 1.25" of extended coverage beyond the push-on molding. Ideal for many modern and classic, trucks, SUVs, EVs, sports cars, sedans and touring cars.

Style A MiniFlaps provide approximately 1" of additional coverage at the bottom of the stone guard.

Style B "low profile" is designed for vehicles with a narrow 0.36"-0.75" fender flange, and provide roughly 0.75" of extended coverage beyond the push-on molding. Ideal for many exotic, sports and muscle cars, modern sedans and touring cars.

Style B MiniFlaps provide approximately 1" of additional coverage at the bottom of the stone guard.

Style W "wide" is designed for vehicles with a wide 1.5"-2.25" fender flange, and provide roughly 1.75" of extended coverage beyond the push-on molding. Ideal for many modern and classic, trucks, SUVs, EVs, sports cars, sedans and touring cars.

Style W MiniFlaps provide approximately 1.25" of additional coverage at the bottom of the stone guard.

We are compiling a list of the many vehicle applications that the Touring Guard fits and will provide recommendations for each model that we have tested. But we are not able to test every possible vehicle and configuration that might be available.

- Please let us know if you find a new application that we can add to our list.

________________________________________________________________

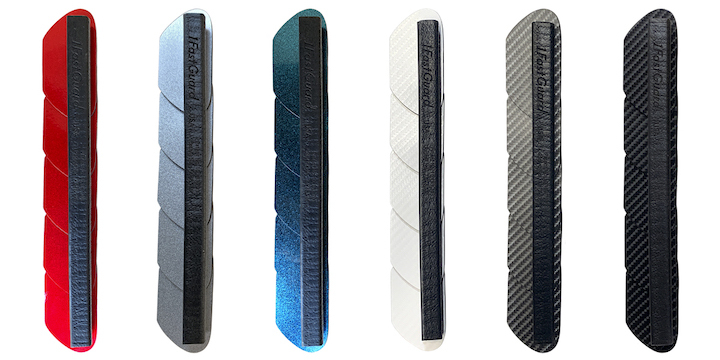

Colors and Finishes

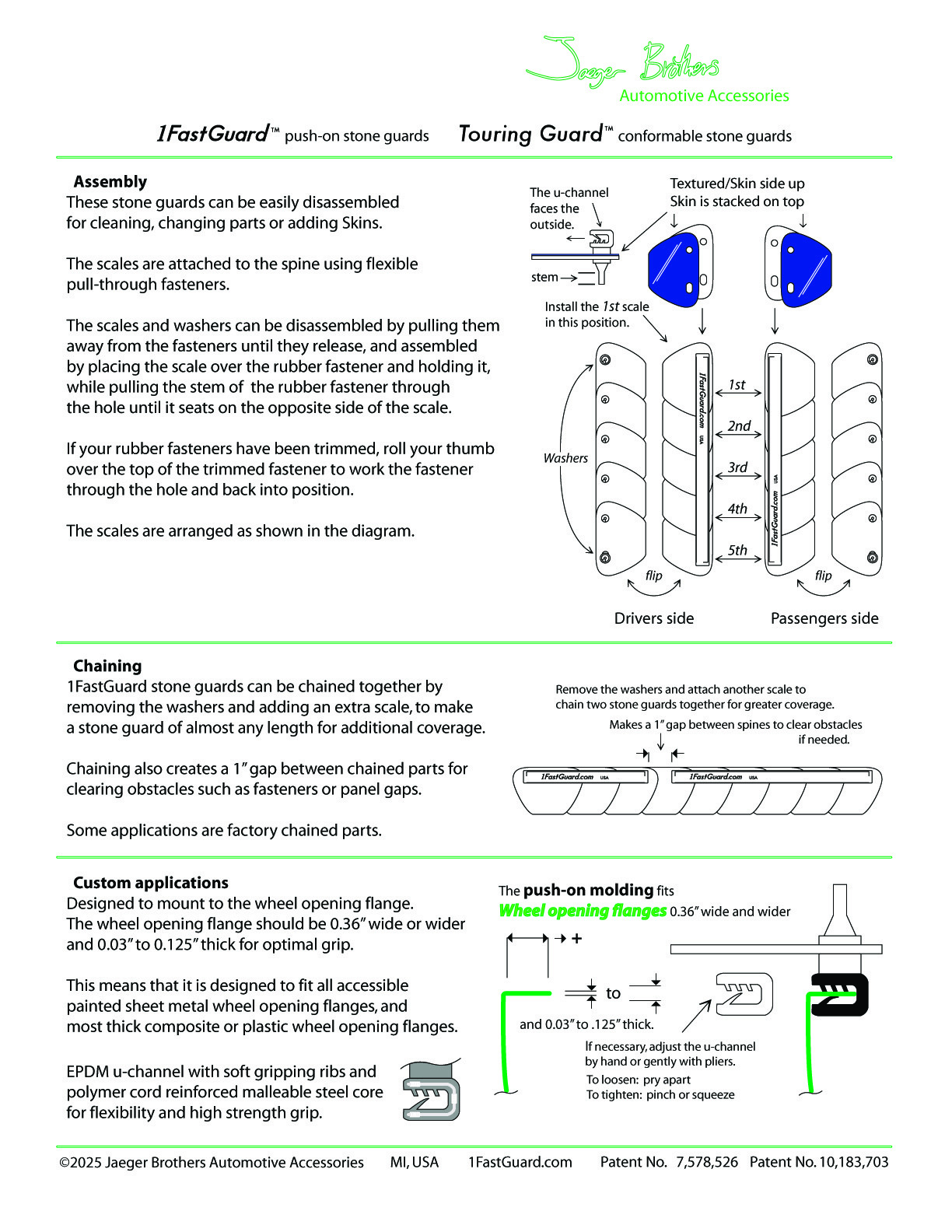

Skins for 1FastGuard stone guards allow you to add your own custom style or finish to your 1FastGuard stone guards, or order a complete set with custom Skins installed.

Skins mount over the top of existing TPV scales on 1FastGuard stone guards for a custom finish and are easy to install or change.

Custom Skins are available in popular simulated Carbon Fiber and metal flake flare look finishes. Custom Skins are also available in gloss clear polycarbonate so you can apply your own vinyl or paint finish, or make a set of clear stone guards.

________________________________________________________________

Installation

________________________________________________________________

Details

All of the parts on the Touring Guard stone guard are made with high quality rubber materials.

A soft EPDM rubber, friction-fit, push-on molding spine slips over the fender edge and holds the splash guard safely and securely in place, yet it can be removed easily for cleaning.

The push-on molding has a malleable metal core that can be adjusted by hand or gently with pliers, to increase grip or to fit over thick or irregular flanges.

The standard overlapping protective scales are made of a soft and durable, 2mm (.080") thick, thermoplastic-rubber composite material (TPV/TPE) for exceptional all-weather durability. The material is textured to mimic common exterior surface textures on modern cars and blend in to the bodywork of the car. Additionally, this material is very easy to cut if you wish to make a custom shaped profile for your vehicle.

The scales are attached to the molding spine using soft rubber pull-through fasteners that make assembly or disassembly for cleaning, or changing colors or styles super easy.

It is a jungle of sand, gravel and crumbling roads out there and we have all had our vehicles assaulted by the hollow thwack of stones bouncing off of our paintwork.

Our job is to help customers protect their vehicles, make them look better and last longer.

Touring Guard stone guards bend to fit, install in seconds and add an effective stone barricade to protect your vehicle.

________________________________________________________________

Known applications include both classic and modern cars

Style A standard profile (TGU-xAx) is designed for vehicles with a wide .75" to 1.5" fender flange, and provide roughly 1.25" of extended coverage beyond the push-on molding.

Style B low profile (TGU-xBx) is designed for vehicles with a narrow 0.36"-0.75" fender flange, and provide roughly 0.75" of extended coverage beyond the push-on molding.

Style W wide (TGU-xWx) is designed for vehicles with a wide 1.5"-2.25" fender flange, and provide roughly 1.75" of extended coverage beyond the push-on molding.

1FastGuard™ Touring Guard™ stone guards fit many makes and models.

And hundreds of other applications with open fender flanges.

________________________________________________________________

Mud flaps vs Splash guards

Mud flaps are normally thought of as a flat flexible piece of rubber that hangs down behind the rear wheels of a large truck. Because they are flapping in the wind they are called flaps. Often weights are added to the bottom of the mud flaps to prevent them from flapping too much. Their primary purpose is to prevent throwing stones into the traffic following the truck, and are required by law for many large trucks.

Mud flap is a term that also applies to many passenger vehicles or rally type vehicles. Still commonly a flat piece of flexible rubber.

Splash guards, stone guards or rock guards are normally a bit smaller than mud flaps. Sometimes factory installed on new vehicles to prevent damage to high wear areas of the vehicle such as the rocker. They are designed primarily to protect the vehicle that they are mounted on rather than the vehicle behind them.

Stone guard or rock guard may also refer to a metal mesh covering for headlights or other fragile exterior components. Stone guard may also refer to a rubber or tape barrier applied directly over the area to be protected such as on the rear arches of vehicles with extra-wide rear fenders.

The main problem with most mud flaps or stone guards, is that they often require professional installation. It may even be necessary to remove the wheel or drill holes in your vehicle. Of course drilling into the body of your vehicle to mount mud flaps often causes permanent damage to the vehicle.

Some manufacturers even recommend applying PPF to your vehicle before installing their products, presumably to prevent the mud flap from rubbing against the paint and causing damage.

The worst part about typical mud flaps or splash guards, is that they are nearly impossible to clean, mud, dirt, grime and moisture can build up between the stone guard and the vehicle. Without deliberate maintenance to remove and clean the mud flaps they can cause additional paint damage to the vehicle all by themselves. Touring Guard stone guards are designed to be easy to remove for cleaning.

Our thoughts on paint protection film (PPF). We think that PPF is a great option for vehicle protection, but it has its own problems. PPF is very pricey and normally requires professional installation. PPF materials are always getting better but do not last forever and eventually must be removed or replaced.

Regarding tape-on stone guards, we have a lot of experience with VHB (very high bond) tapes and have used many different types and styles. In fact we we still offer our own tape product XFlaps. The problem with tape is that if the mating surfaces are not the same shape, over time the tape will peel itself up from the surface, flat splash guards installed against a curved surface will all fail eventually, according to our testing and experience. The results can be improved using adhesive accelerators but I would personally never apply something like that to the paint finish of a car.

Additionally, both tape and PPF are prone to creep. When creep occurs, exposed adhesive collects dirt around the edges of the product, to maintain a clean appearance the tape or PPF needs to be replaced periodically.

________________________________________________________________

Introducing the Touring Guard stone guard.

Can be installed or removed in seconds with no tools or any other fasteners, by almost anyone.

Its patented conformable design allows it to bend in three dimensions to fit nearly any fender flange.

Touring Guard stone guards are designed to protect the most vulnerable parts directly behind the tire and downstream of the tire on the side of the vehicle.

Touring Guard stone guards offer thick rubber that extends far beyond the PPFs typical protection range, and will protect both your car and your PPF, for a fraction of the cost.

Thank you taking a few moments to learn about our products. If you ever have any questions or comments please don't hesitate to contact us. J&J